Iingxaki eziqhelekileyo kunye nezisombululo zoMbala we-Pervious Concrete

1. Amandla angonelanga oMbala wekhonkrithi engapheliyo

Amandla ekhonkrithi engabonakaliyo achaphazeleka kwizinto ezininzi, ngokukodwa kubandakanywa: ukongezwa kwe-samente okwaneleyo, amandla anganeleyo amatye, iteknoloji yokulungiselela, ukungonelanga kwe-arhente yokuqinisa i-SiO2 umxholo, kunye nokugcinwa okungaqhelekanga. Ngoko ke, kufuneka iqale ekulungiseni izinto eziluhlaza, ukongeza izongezo zeminerali kunye nokuqiniswa kwezinto eziphilayo Imiba emithathu yokuphucula amandla ekhonkrithi engapheliyo.

2. Umbala wokuqhekeka kwekhonkrithi eqhubekayo

Ngenxa yokutshintsha kweqondo lokushisa kunye nomswakama, ukunyanzeliswa kunye nokungalingani kwekhonkrithi, kunye nesakhiwo esingenangqiqo, iintanda zihlala zibonakala kwikhonkrithi engapheliyo emva kokusetyenziswa ixesha elithile, kubangela iintloko kubasebenzi abaninzi bokwakha. Ngoko ke, xa uyila ukudibanisa, ingqalelo kufuneka ihlawulwe ekunciphiseni ukusetyenziswa kwamanzi ngelixa uqinisekisa ukuba ikhonkrithi ekhoyo isebenza kakuhle. Cwangcisa ukuqiniswa okufihliweyo kwimida eqhekekileyo ngokulula ukunyusa umlinganiselo wokuqiniswa kunye nokomelela kokugqibela kwekhonkrithi. Kuyilo lolwakhiwo, iimpawu zemozulu ngexesha lokwakhiwa kufuneka ziqwalaselwe ngokupheleleyo kwaye amajoyina emva kokuthulula kufuneka abekwe ngokufanelekileyo. Lawula ngokungqongqo umgangatho kunye nemigangatho yobugcisa bezinto eziphathekayo eziphathekayo, sebenzisa i-samente yobushushu obuphantsi be-hydration, kunye nokunciphisa umxholo wodaka we-aggregates erhabaxa kunye necolekileyo kangangoko kunokwenzeka (ngaphantsi kwe-1 ukuya kwi-1.5%).

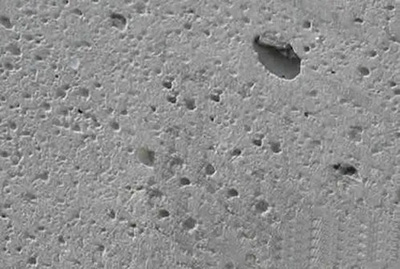

3. Imingxunya okanye amaqamza avela kuMbala wekhonkrithi

Esona sizathu sisisiseko sokwenziwa kwemingxuma emininzi kumbala wekhonkrithi ekhoyo kukuba isinyibilikisi kwipeyinti yomgangatho ovuzayo siyasebenza emva kokupeyinta, sishiya ulwelo lwepeyinti kade kakhulu ukuba lungazalisa, nto leyo ekhokelela kwizangqa ezincinci, imingxuma okanye imingxunya. Ikhonkrithi evumelekileyo kunye ne-varnish ephantsi kunye nomxholo we-pigment kwi-surface layer ixhomekeke kule meko.

4. Amatye angaphelelanga awayo kwikhonkrithi enombala otyhutyhayo

Ezona zizathu ziphambili zokuxobula le ndawo kwikhonkrithi engapheliyo zezi zilandelayo: Umlinganiselo onganelanga wesixhasi sekonkrithi esivumlekayo (izinto zesamente) kunye nesamente okanye ukuxuba okungalinganiyo; ukunkcenkceshela ngokugqithisileyo phezu komhlaba, ukulahlekelwa kwe-slurry phezu kwamatye; amandla angonelanga ekhonkrithi; naxa uhlamba iindawo ezingqongileyo. Udaka luyalahleka ngenxa yokhukuliseko lwamanzi; ifilimu yokunyanga ayikho. Ngoko ke, kuyimfuneko ukusebenzisa izixhobo ze-ejenti zokuqinisa ikhonkrithi evunyiweyo; i-ejenti yokuqinisa kunye nesamente kufuneka ifakwe kwiimali ezaneleyo kwaye ixutywe ngokucokisekileyo njengoko kufuneka. Xa utshiza amanzi okugcinwa, uxinzelelo akufanele lube phezulu kakhulu, kwaye ukutshiza ngokuthe ngqo ngemibhobho yamanzi kunqatshelwe ngokungqongqo. Xa uhlambulula indawo ejikelezileyo, gubungela inxalenye yekhonkrithi evuzayo. Qhuba ulwakhiwo lwe-batching ngokomlinganiselo owenziweyo wamandla ekhonkrithi. Ukugqithisa ifilimu yokunyanga kufuneka ivalwe ngokuqinileyo, kwaye ifilimu kufuneka igubungele kwaye iphiliswe iintsuku ezi-7.