Stamped Concrete Mold

The advantage of concrete embossed rubber molds is that they have excellent weather resistance, toughness and resistance to wear and tear, which makes it a commonly used mold material for the production of various fine concrete products.

First, due to the greater elasticity of the rubber material, the rubber mold can better adapt to the flow and pressure of the concrete, thus better maintaining the integrity and detail of the pattern.

Secondly, the weather resistance and toughness of the rubber mold allow it to be used in various climatic conditions and is not prone to problems such as cracking and deformation, thus improving the service life and stability.

In addition, the rubber mold's ease of cleaning and resistance to adhesion to concrete also make it more convenient and faster to use, which can greatly improve construction efficiency.

In summary, the excellent characteristics of concrete embossed rubber molds allow it to be widely used in the production and decoration of various concrete products, bringing more choices and convenience to the construction industry.

>Unique, Artistic and Abundant Rubber Patterns are with abrasion resistant, high elasticity, strong compression, heat resistant, clear texture & easy to stamp and bend resistant.

>It is mixed with concrete as a new construction technology and in recent years it has been teated as a new kind of wall and road pavement material.

>It is beautiful, wear-resisting, environmental protection, novel, strong simple-sense , and lasting color, durable and so on.

>Not only adornment sense is strong, and the compressive flexural strength is 2 to 3 times more than ordinary concrete.

>It is the ideal replacement of square brick, floor tile, the Netherlands brick,etc.

> Can do ODM/OEM order.

> Can change the color of the mould for free.

Shaping Mode: Compression Mould

Product Material:Polyurethane

Mold Material: Environmental-Friendly PU

Feature:Beautiful ,economical ,Wear-resisting ,Good compression resistance

Application:Garden Paving,Driveway, Pool Deck, Patio

Product life: Min.5 Years

Abrasion performance:Strong

Size: Muti-Size

Design:Wood Grain,Cobblestones,European Fan etc

Certification:ISO9001:2015

Packaging:By Carton or Bag acc. to Customers' Requirement.

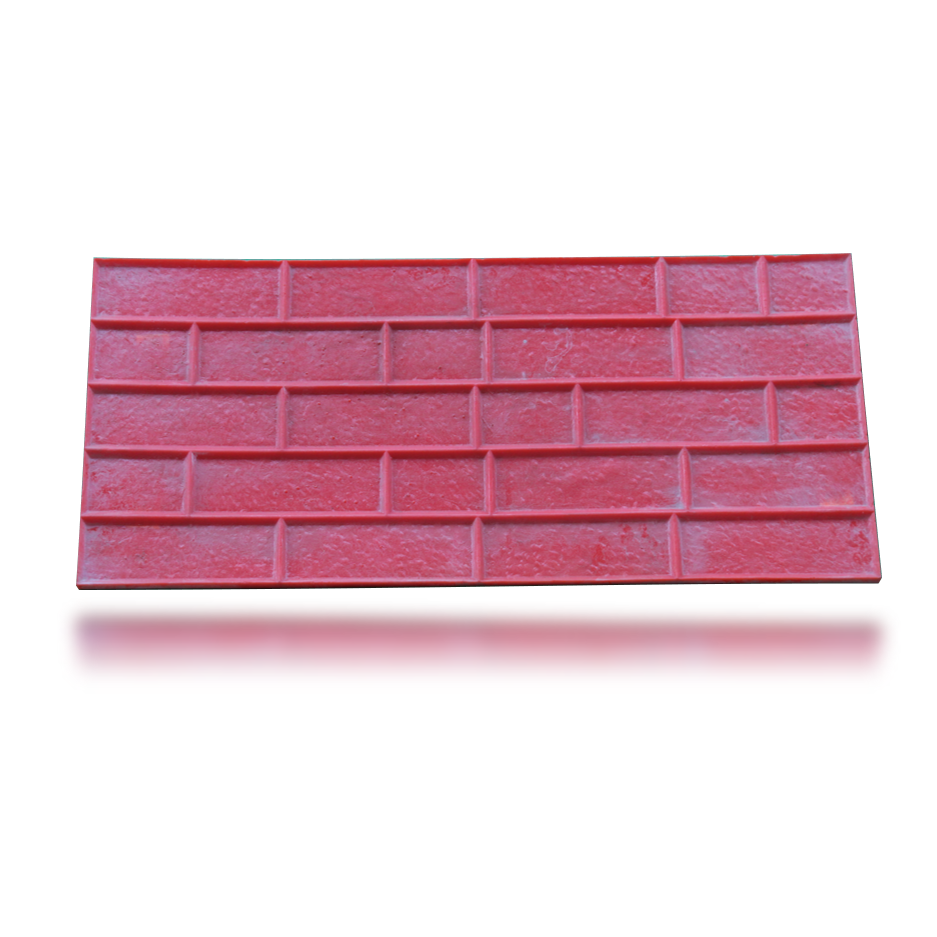

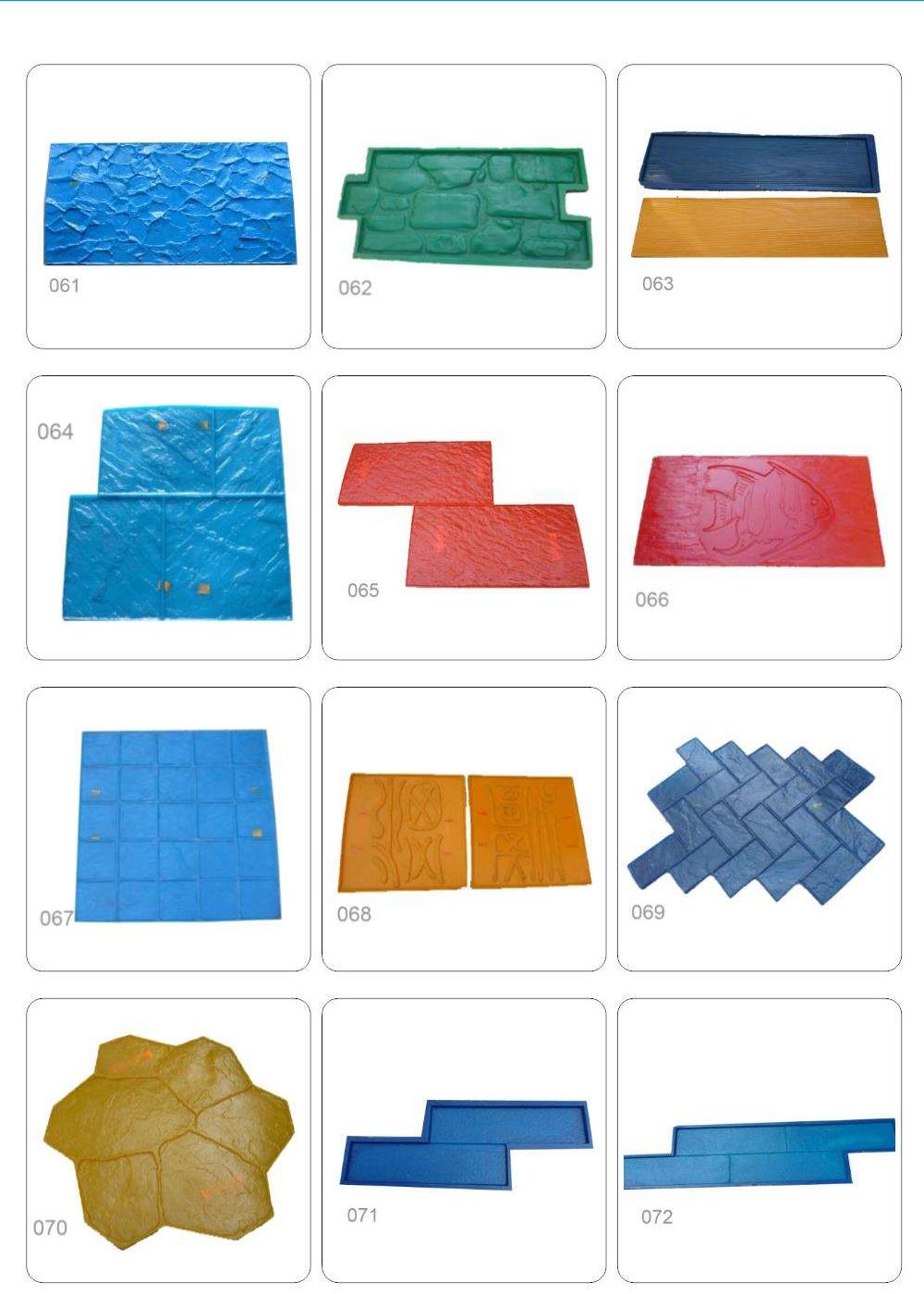

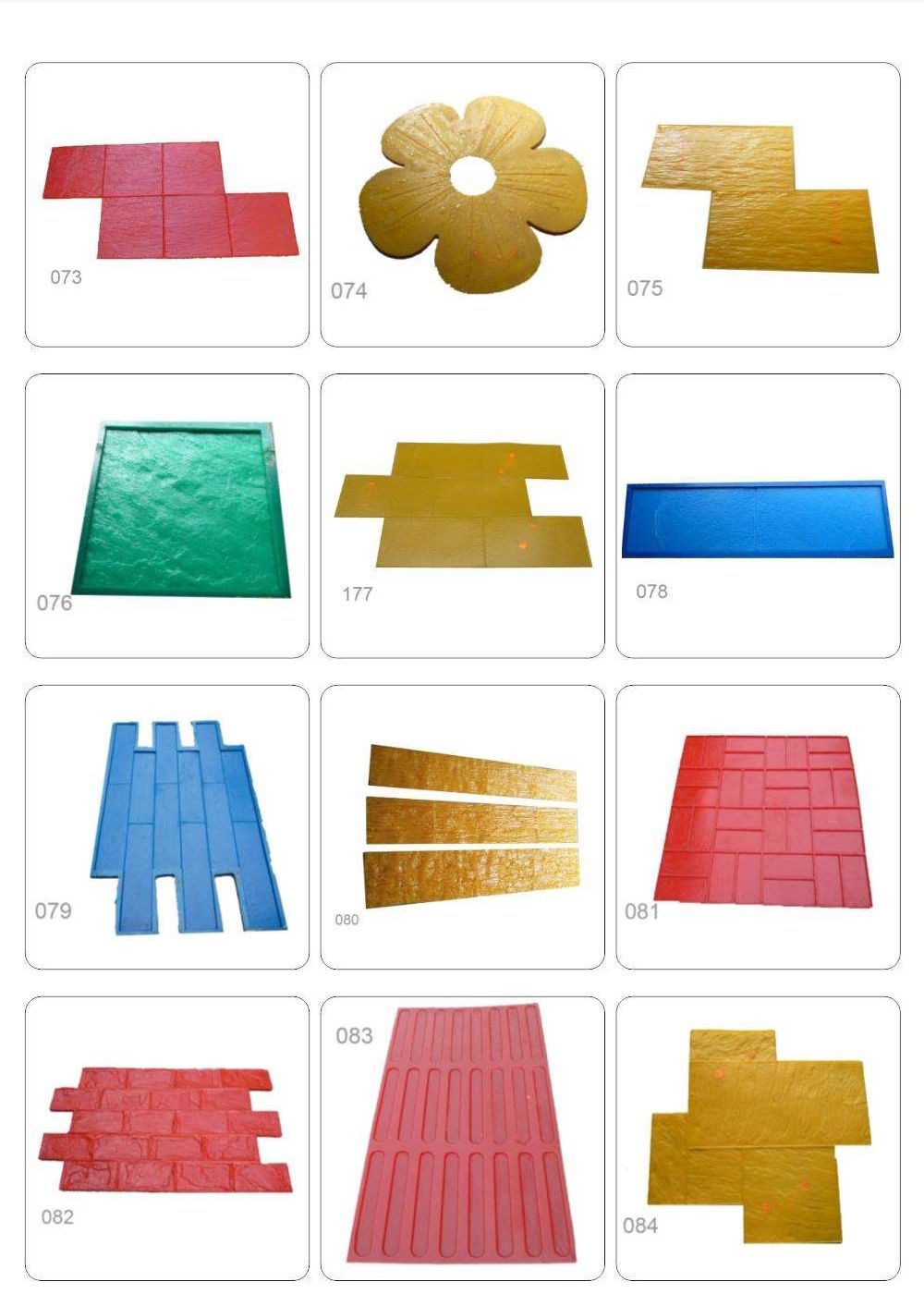

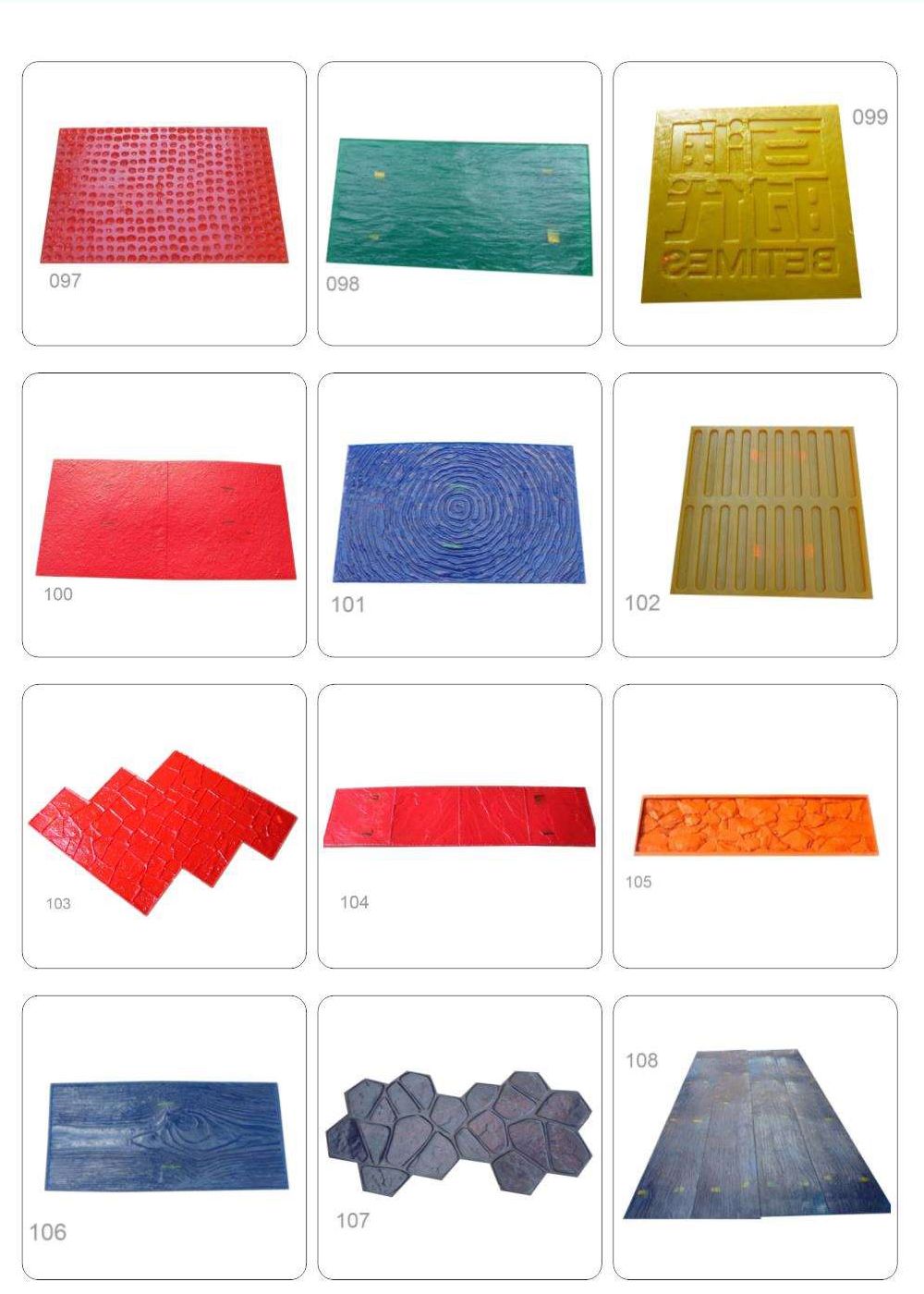

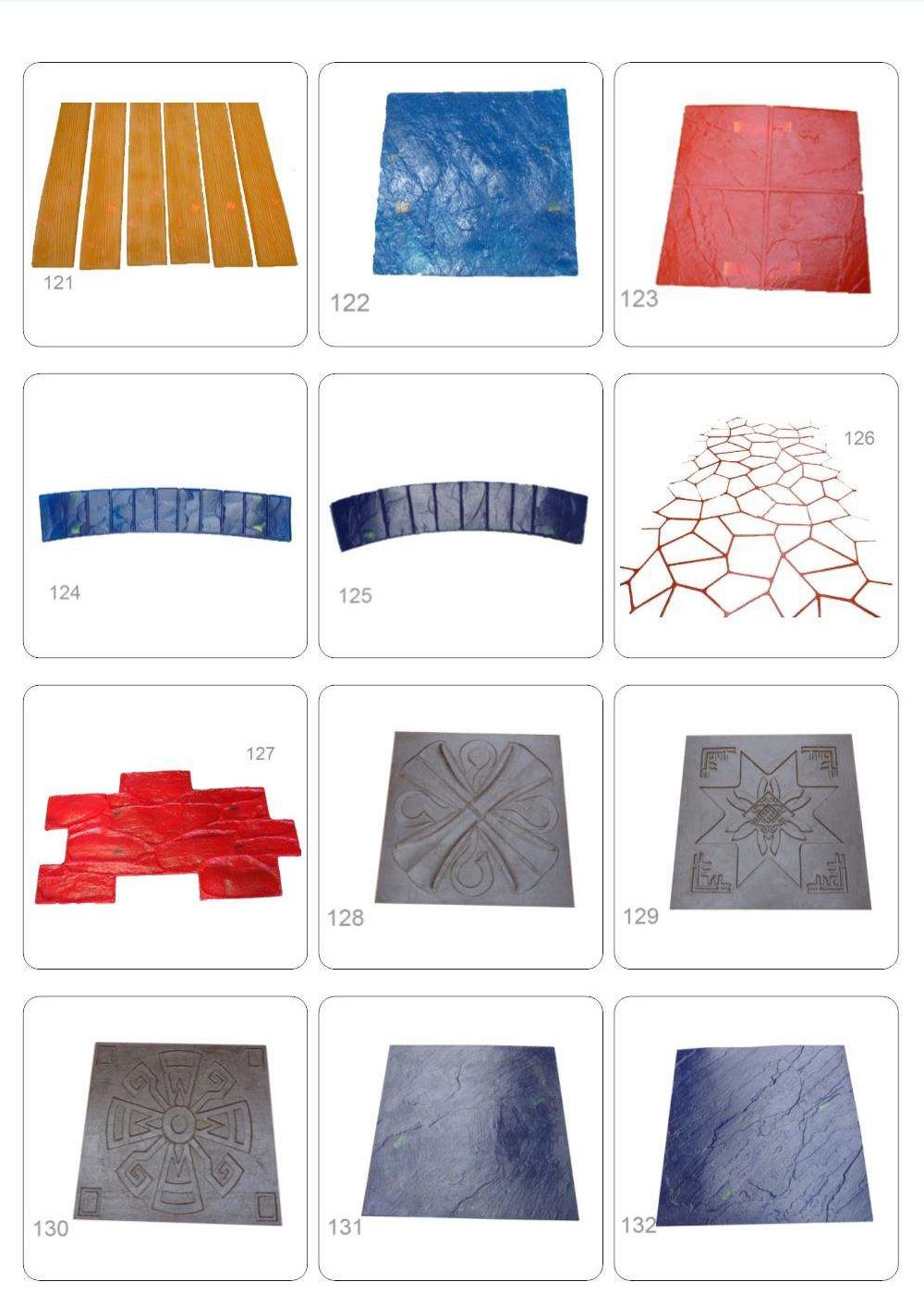

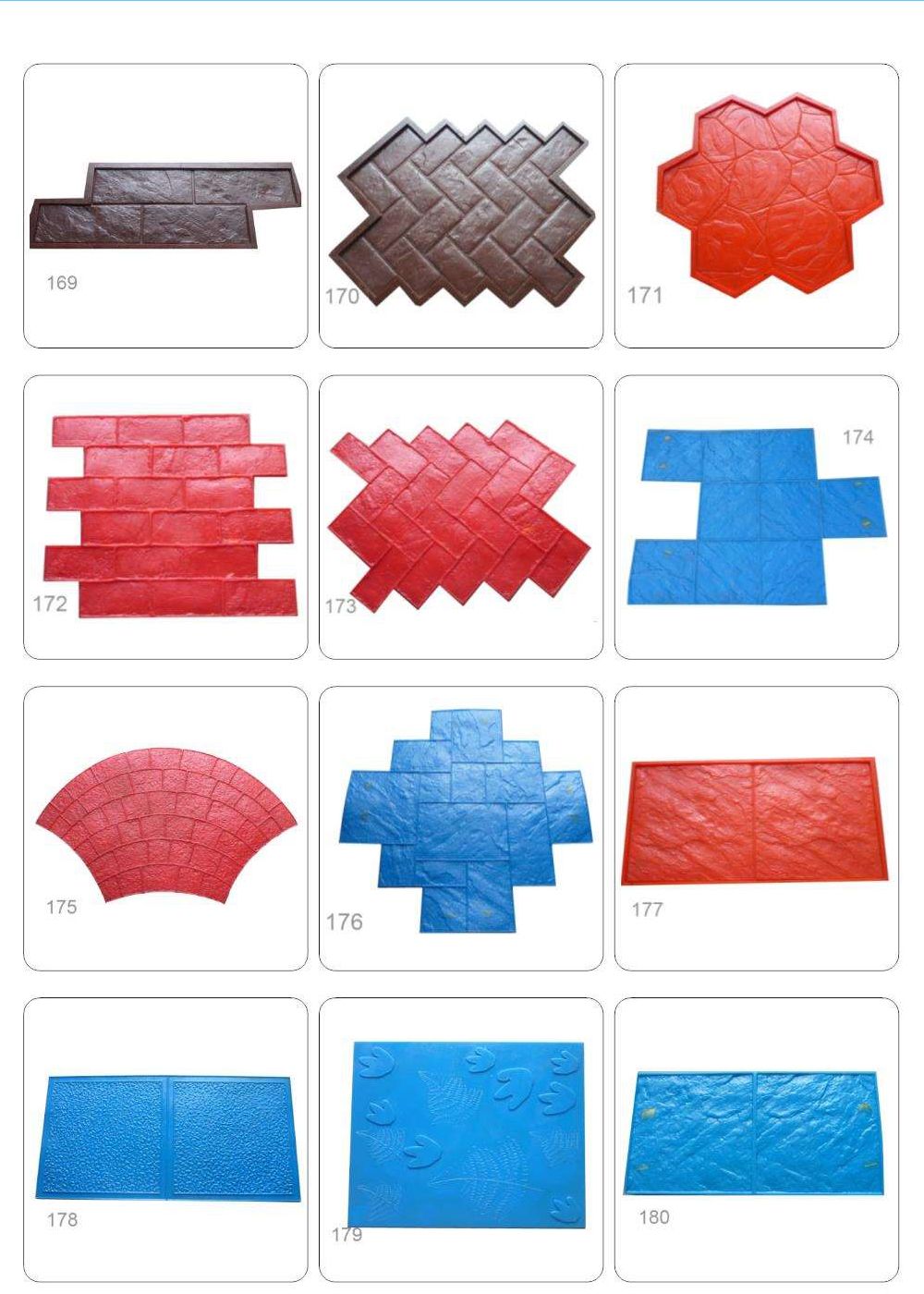

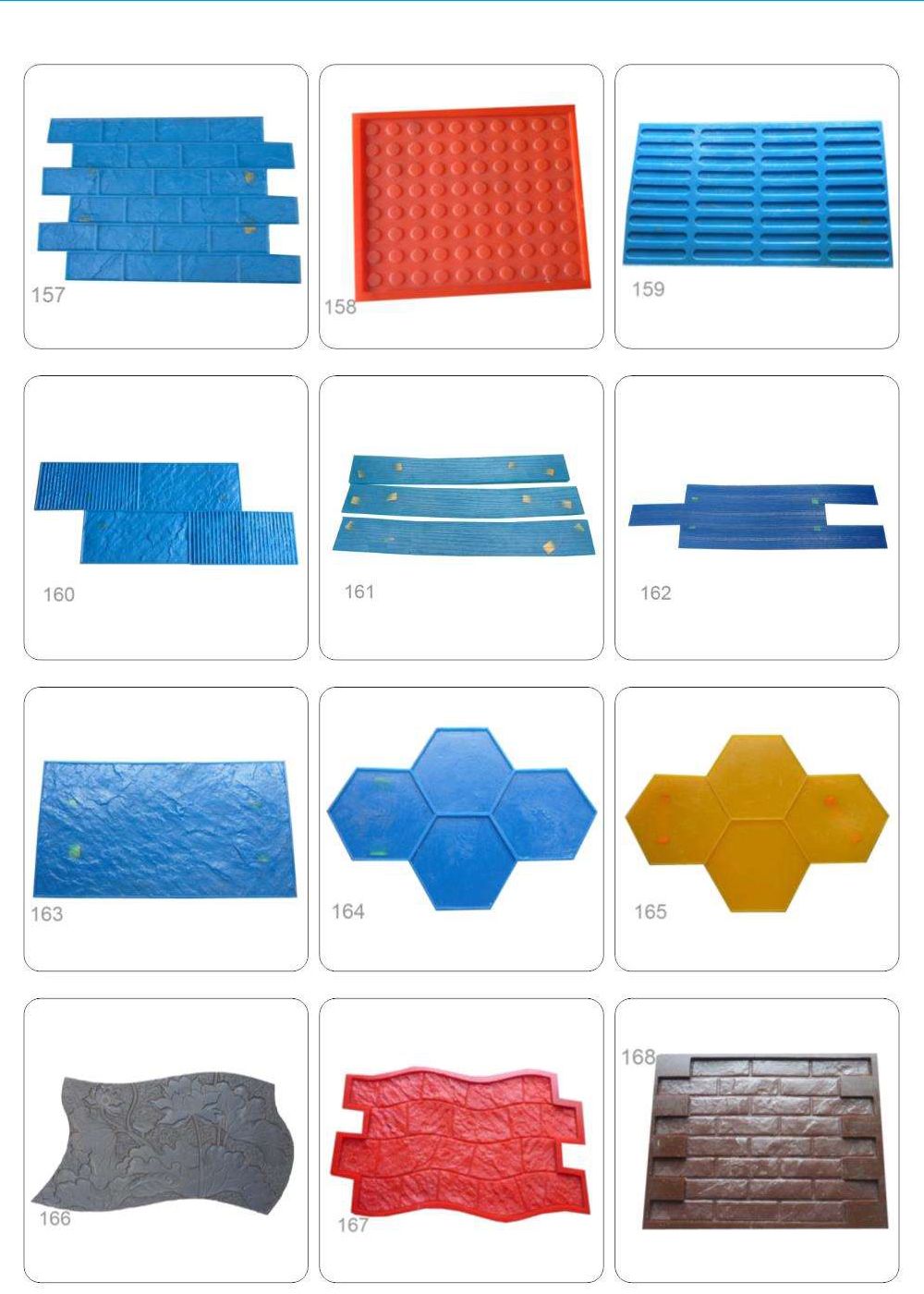

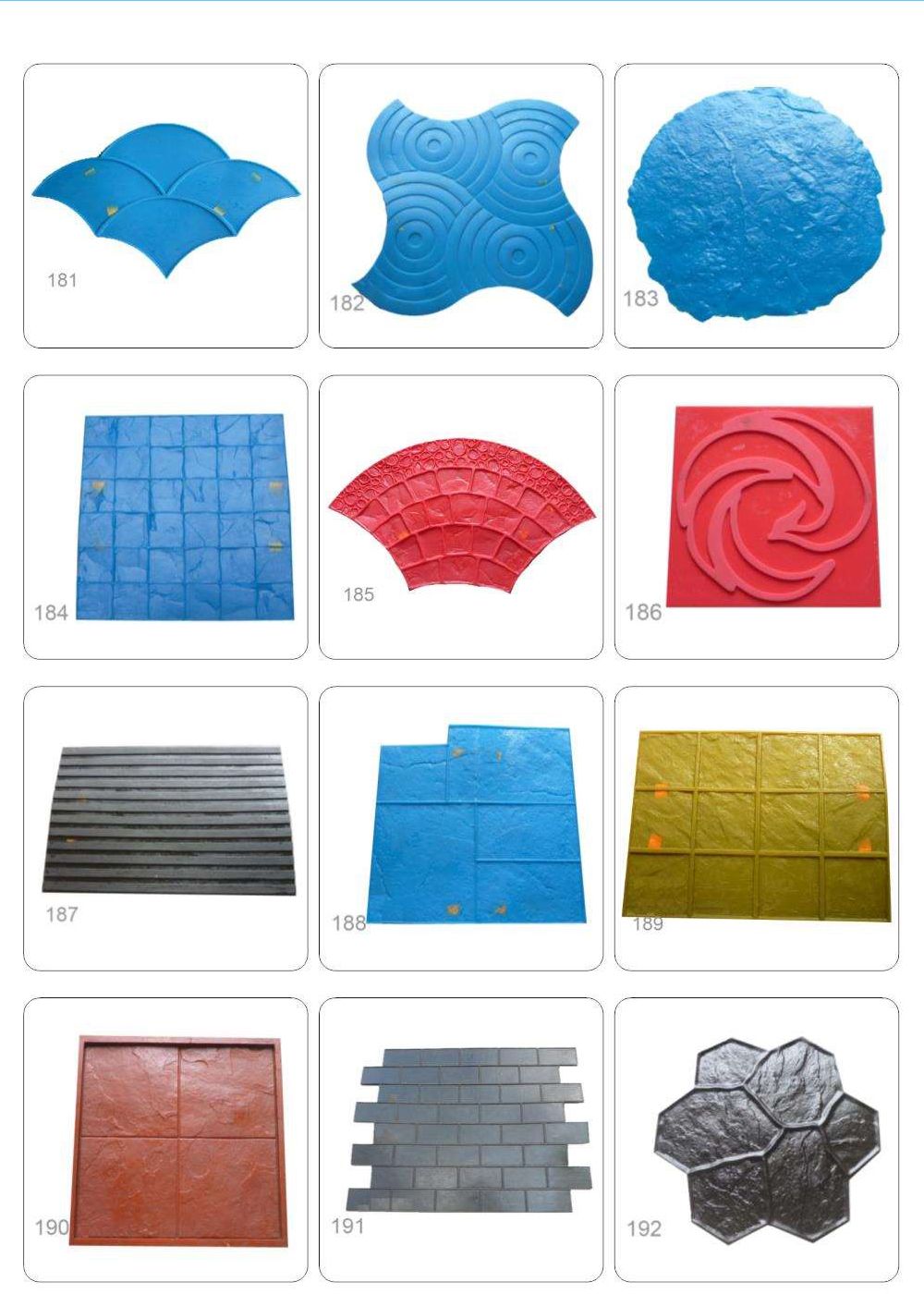

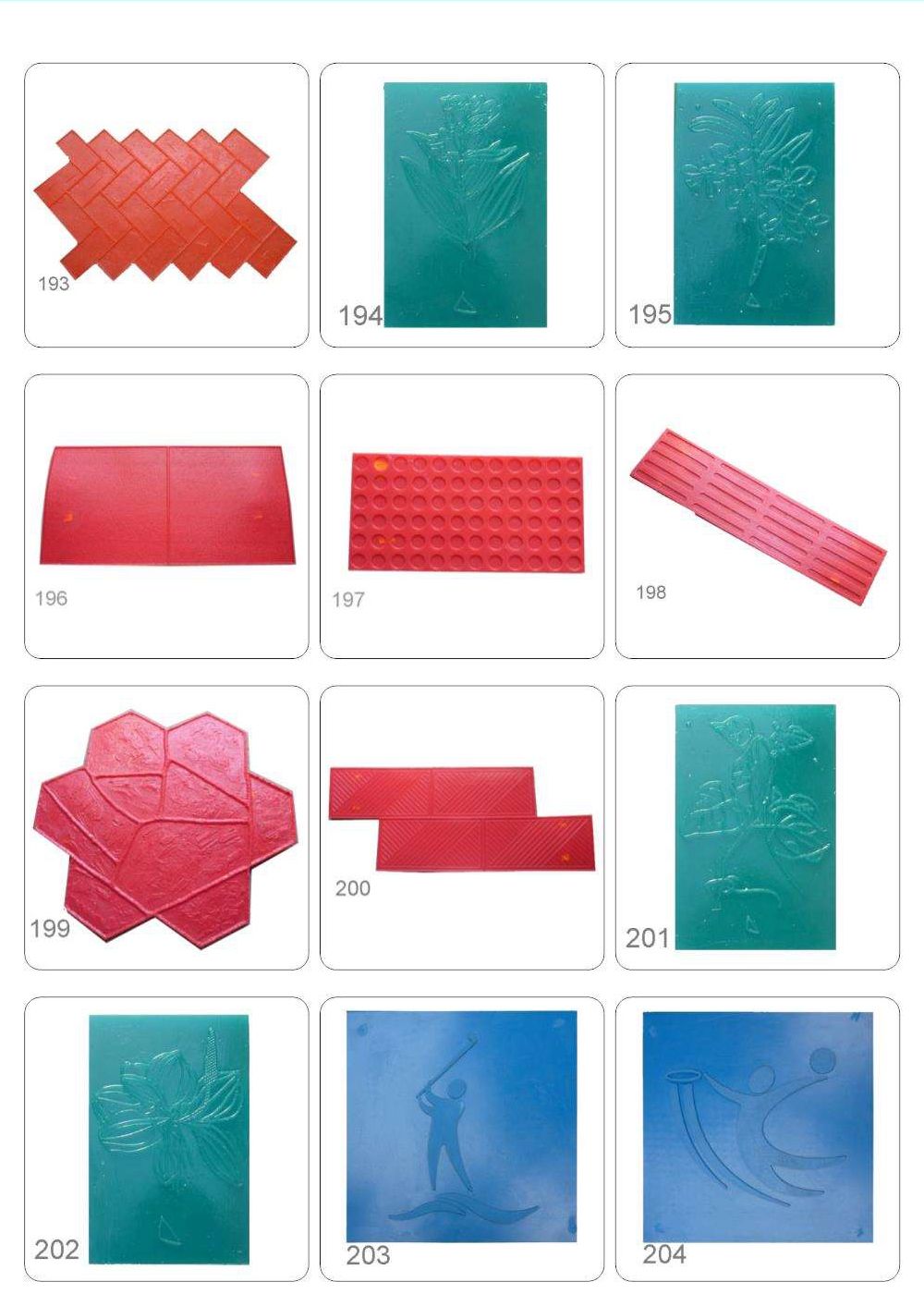

There are many types of Stamped concrete mold. BES has nearly a hundred kinds of embossing molds. The following types are currently common on the market:

Masonry Stamped concrete mold: The surface of this mold has masonry patterns of various shapes and textures. The masonry pattern is embossed into the concrete surface through pressure, thereby creating an antique masonry effect.

Stone Stamped concrete mold: The surface of this mold has slate patterns of various shapes and textures. The slate pattern is embossed onto the concrete surface through pressure, thereby creating the effect of antique stone.

Wood grain stamped concrete mold: The surface of this mold has wood grain patterns of various shapes and textures. The wood grain pattern is embossed onto the concrete surface through pressure, thereby creating an imitation wood grain effect.

Pattern stamped concrete mold : The surface of this mold has patterns of various shapes and textures. By pressing the pattern into the concrete surface, various decorative effects can be created.

Three-dimensional stamped concrete mold: The surface of this mold has three-dimensional patterns of various shapes and textures. The three-dimensional pattern is embossed onto the concrete surface through pressure, thereby creating a three-dimensional effect.

In addition, there are also types of stamping molds for flowers, animals, letters, etc., which can be selected and used according to specific needs. In general, the choice of concrete embossing mold types should depend on the specific application scenarios and needs.